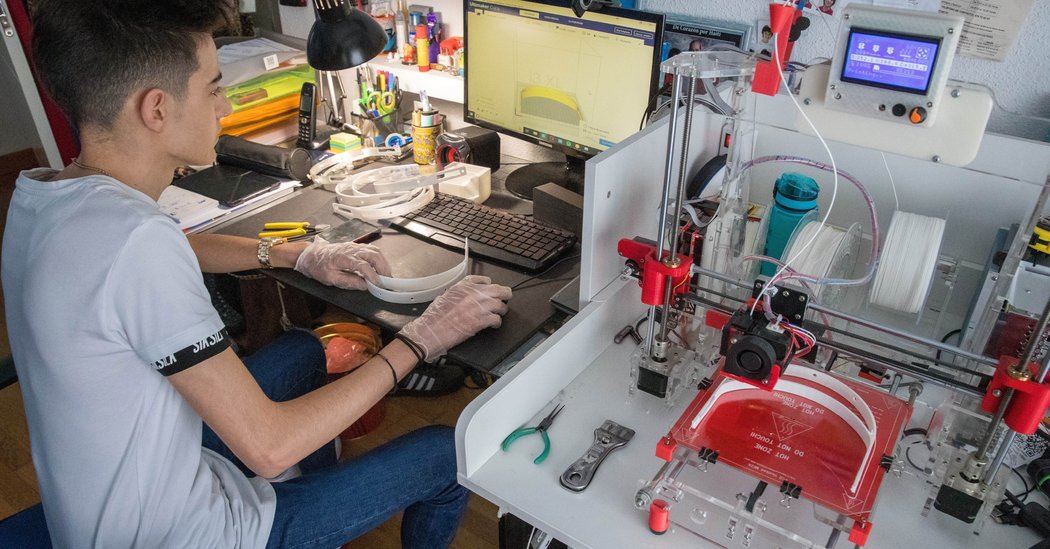

Health and fitness treatment staff around the world are inquiring for support. “What do you want?” “PPE.” “When do you will need it?” “Now.” They’re in desperate need of additional PPE, also identified as individual protective devices. Shares of the crucial equipment are disappearing all through the coronavirus pandemic. Medical practitioners say they are rationing gloves, reusing masks and raiding components shops. The C.D.C. has even said that scarves or bandannas can be utilized as protection as a very last resort. “I’ve satisfied the medical doctors, and talked with them each day. I think there is an exciting problem below in that, at present, there is these kinds of a need to have that if they experienced anything at all, they would deploy it.” The cries for enable are mobilizing a broad vary of innovators, some of them even signing up for forces by on the web messaging platforms like Slack. These are engineers, health professionals and even superior college students from about the environment. They appear from all walks of life, but say their goal is the exact. “It’s incredible because no one’s asking which region are you from? They are just like, how can I aid? What do you need?” They are pitching in by crowdsourcing models for masks, experience shields and even ventilators that could be reproduced about the world. This is Nick Moser. He’s an lively player in a single of the maker groups. His working day career is at a structure studio. Now, he’s developing replicable experience masks. “We’re concentrated on a few goods: a encounter shield, a fabric mask and an alternate to N95-rated respirators. The encounter protect is the to start with line of defense for health-related employees. It guards towards droplets. If a individual coughs, it’ll strike the encounter shield relatively than them.” Some models are made employing 3-D printers or laser cutters. “There you go.” Then, the prototypes are field-tested by well being treatment staff. Even some college labs are experimenting with Do-it-yourself techniques. A team at Ga Tech is doing the job with open up-source layouts from the net to produce products. “My lab is effective in the space of frugal science, and we develop reduced-charge tools for resource-restricted areas. And now, we have understood that I do not have to go that much. It’s in our yard, proper? We want it now. So this is a plastic sheet I have — not also distinct from what you would get out from a 2-liter Coke or a soda bottle. I in fact acquired this from an artwork keep. It’s just sheets of PET, so we can reduce these out. We are contacting this an origami face shield, and it is the Level 1 safety. This is a single thought. There are multiple distinct prototypes.” “This headband can be reused, and a doctor or nurse could just generally tear this off and fundamentally snap another one particular on. We’re hearing that, in some cases, that they go through close to 2,000 of these a day.” Since the will need is escalating so speedily, the makers are also considering about how to maximize their output. “So how do we get from this 1 that anyone produced at dwelling on a laser cutter or a 3-D printer, and then get it in the palms of hundreds of physicians and front-line employees?” They’re doing work with mass suppliers that can get their examined models, and replicate them at a bigger scale. “We’ve been on the cell phone chatting to a variety of suppliers, material suppliers. So I imagine a person of the neat items that we’ve performed is not only the structure, proving that you can make it rapidly, but then also striving to protected the whole offer chains.” This is Dr. Susan Gunn, whose clinic system in New Orleans has even began its possess initiative to 3-D print machines. “So it starts with an notion. We place the thought into position. And then we make positive that it is professional-quality 1st. An infection manage is hunting at it, and we’re creating confident that we’re employing the right elements that would be accredited by the C.D.C. and the Environment Overall health Organization.” Dr. Gunn suggests the gear is a safe substitute for individuals who may in any other case confront a shortage. “We’re building facial area shields and we’re generating these different PPEs, and we’re placing them in the palms the place persons felt like they required them.” A different critical piece of devices is the N95 mask, and the supply is dwindling speedy. Nick and his workforce are building a strong different for this mask that can hold any filter content, and be mass made. “It is easily printable. This one is utilized in health care scenarios the place there is an actively infectious affected person. So nursing households or clearly I.C.U. units would be the target to get these.” “These are definitely difficult objects to manufacture mainly because you’re heading to give it to a nurse, and then I want to be seriously confident that it will not allow a virus by, proper?” This equipment is not approved by federal businesses, but the designers are testing their respirator prototypes for safety. “That was basically the initial, pretty much the initially issue that was requested. Can we do just about anything which is basically heading to be safe and sound and helpful?” Some makers are pursuing even far more bold jobs. An engineer named Stephen Robinson in New Haven, Conn., is doing the job on planning ventilators to enable individuals breathe. Nations around the world are experiencing a dire scarcity of the lifesaving devices. Ideal now, these Do it yourself ventilators are nonetheless prototypes. “So actually, this should really be assumed of as the seed of an notion that could likely be grown with, and totally demanding, the health care and the tech communities.” But they could turn into critical if essential provides run out. “We’re in pretty unsure situations, and I see explorations and tasks as sort of an insurance coverage plan that could probably be leaned on if there was intense situation.” Overall health care staff are hopeful that these endeavours could avoid an even worse result. “We never want any one — let us be apparent — to use a bandanna to guard by themselves. I hope it never ever gets to the point where we have to use a bandanna. And I do not believe, with this initiative that we will get there.” For innovators like Saad, the challenge is personal. “I just just can’t end. I have to do stuff. And then I’m presently at a medical center. That’s why I have this uplifting small flower portrait. We’re expecting a infant boy, and what do we tell him when he grows up about what we did when culture needed us?”